+86 13777722188

+86 13777722188

01

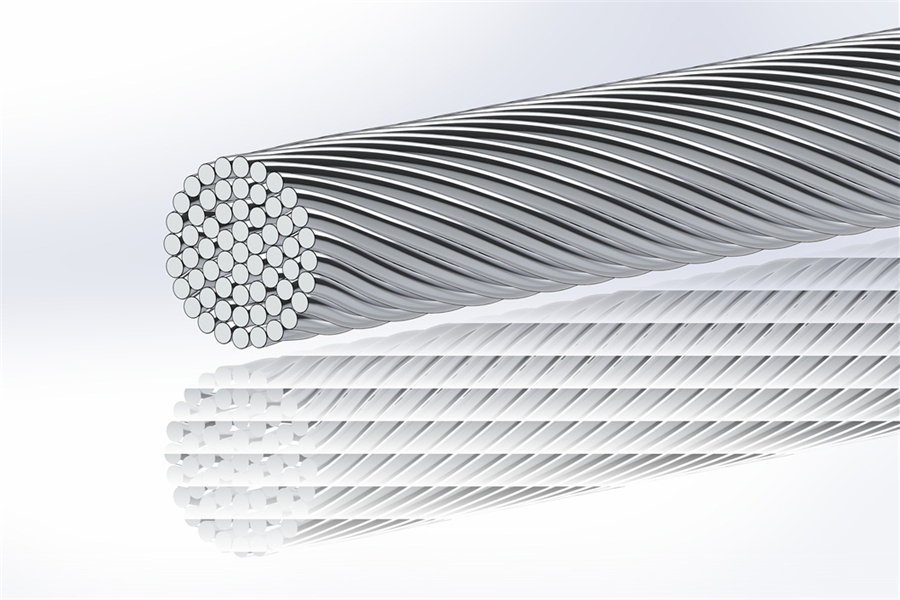

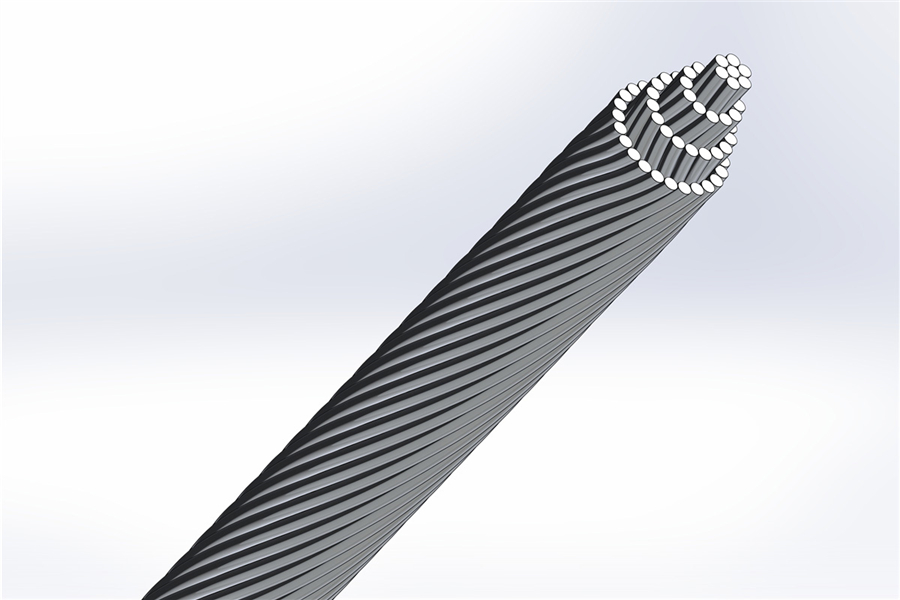

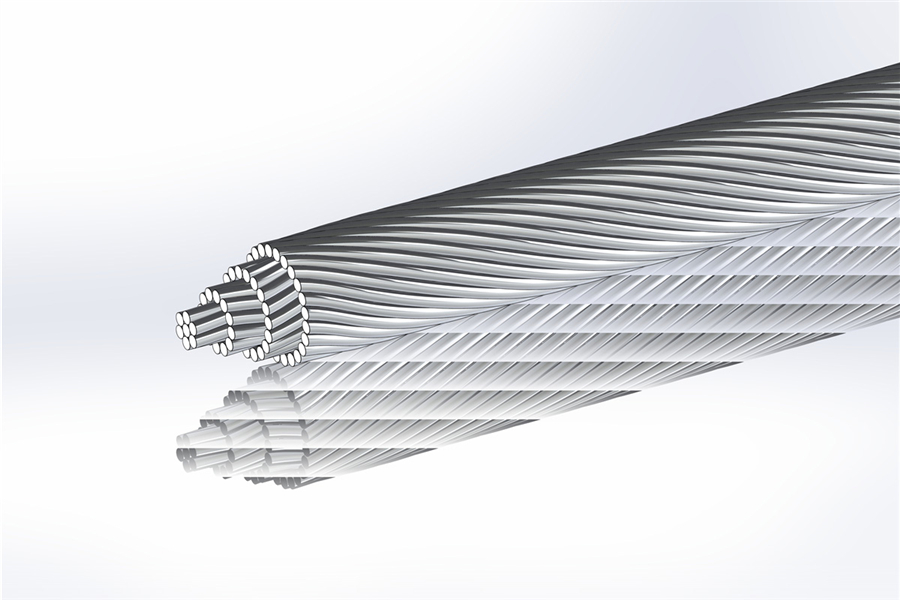

AAAC BS EN 50182 BS3242 All Aluminum Alloy Conductor

Product application

In industrial zones with heavy pollution, AAAC aluminum alloy conductors maintain stable performance against chemical exposure, ensuring uninterrupted power supply for factories and manufacturing facilities.

AAAC Standard:BS EN 50182 (Old Standard: BS 324)

| Aluminum Alloy Conductor(AAAC) | ||||||||

| Code Name | Old Code Name | Sectional Area | Wire Diameter&Stranding | Diameter of Conductor | Nominal Breaking Load | Linear Mass | Maximum Resistance at 20℃ | |

| mm2 | mm | No. | mm | kN | kg/km | Ω/km | ||

| 19-AL3 | BOX | 18.8 | 1.85 | 7 | 5.55 | 5.55 | 51.5 | 1.748 |

| 24-AL3 | ACACIA | 23.8 | 2.08 | 7 | 6.24 | 7.02 | 65.1 | 1.3828 |

| 30-AL3 | ALMOND | 30.1 | 2.34 | 7 | 7.02 | 8.88 | 82.4 | 1.0926 |

| 35-AL3 | CEDAR | 35.5 | 2.54 | 7 | 7.62 | 10.46 | 97.1 | 0.9273 |

| 42-AL3 | DEODAR | 42.2 | 2.77 | 7 | 8.31 | 12.44 | 115.5 | 0.7797 |

| 48-AL3 | FIR | 47.8 | 2.95 | 7 | 8.85 | 14.11 | 131.0 | 0.6875 |

| 60-AL3 | HAZE | 59.9 | 3.30 | 7 | 9.9 | 17.66 | 164.0 | 0.5494 |

| 72-AL3 | PINE | 71.6 | 3.61 | 7 | 10.83 | 21.14 | 196.2 | 0.4591 |

| 84-AL3 | HOLLY | 84.1 | 3.91 | 7 | 11.73 | 24.79 | 230.2 | 0.3913 |

| 90-AL3 | WILLOW | 89.7 | 4.04 | 7 | 12.12 | 26.47 | 245.7 | 0.3665 |

| 119-AL3 | OAK | 118.9 | 4.65 | 7 | 13.95 | 35.07 | 325.5 | 0.2767 |

| 151-AL3 | MULBERRY | 150.9 | 3.18 | 19 | 15.9 | 44.52 | 415.2 | 0.2192 |

| 181-AL3 | ASH | 180.7 | 3.48 | 19 | 17.4 | 53.31 | 497.3 | 0.1830 |

| 211-AL3 | ELM | 207.6 | 3.73 | 19 | 18.65 | 62.24 | 571.3 | 0.1568 |

| 239-AL3 | POPLAR | 239.4 | 2.87 | 37 | 20.09 | 70.61 | 660.2 | 0.1387 |

| 303-AL3 | SYCAMORE | 303.2 | 3.23 | 37 | 22.61 | 89.4 | 836.2 | 0.1095 |

| 362-AL3 | UPAS | 362.1 | 3.53 | 37 | 24.71 | 106.82 | 998.8 | 0.0917 |

| 422-AL3 | WALNUT | 421.8 | 3.81 | 37 | 26.67 | 118.17 | 1163.5 | 0.0786 |

| 479-AL3 | YEW | 479.0 | 4.06 | 37 | 28.42 | 141.31 | 1321.2 | 0.0693 |

| 498-AL3 | TOTARA | 498.1 | 4.14 | 37 | 28.98 | 146.93 | 1373.8 | 0.0666 |

| 587-AL3 | RUBUS | 586.9 | 3.50 | 61 | 31.5 | 173.13 | 1620.9 | 0.0567 |

| 659-AL3 | SORBUS | 659.4 | 3.71 | 61 | 33.39 | 194.53 | 1821.3 | 0.0505 |

| 821-AL3 | ARAUCARIA | 821.1 | 4.14 | 61 | 37.26 | 242.24 | 2267.9 | 0.0406 |

| 996-AL3 | REDWOOD | 996.2 | 4.56 | 61 | 41.04 | 293.88 | 2751.5 | 0.0334 |

| Note:The outermost layer is twisted to the right (Z). | ||||||||

| Aluminum Alloy Conductor(AAAC) | ||||||||

| Code Name | Old Code Name | Sectional Area | Stranding & Wire Diameter | Diameter of Conductor | Nominal Breaking Load | Linear Mass | Maximum Resistance at 20℃ | |

| mm2 | mm | No. | mm | kN | kg/km | Ω/km | ||

| 239-AL5 | POPLAR | 239.4 | 2.87 | 37 | 20.09 | 70.61 | 660.1960325 | 0.1330 |

| 303-AL5 | SYCAMORE | 303.2 | 3.23 | 37 | 22.61 | 89.44 | 836.207698 | 0.1050 |

| 362-AL5 | UPAS | 362.1 | 3.53 | 37 | 24.71 | 106.82 | 998.7539902 | 0.0879 |

| 479-AL5 | YEW | 479.0 | 4.06 | 37 | 28.42 | 141.31 | 1321.177545 | 0.0665 |

| 498-AL5 | TOTARA | 498.1 | 4.14 | 37 | 28.98 | 146.93 | 1373.756622 | 0.0639 |

| 587-AL5 | RUBUS | 586.9 | 3.50 | 61 | 31.5 | 173.13 | 1620.946812 | 0.0544 |

| 659-AL5 | SORBUS | 659.4 | 3.71 | 61 | 33.39 | 194.53 | 1821.295838 | 0.0484 |

| 821-AL5 | ARAUCARIA | 821.1 | 4.14 | 61 | 37.26 | 242.24 | 2267.949386 | 0.0389 |

| 996-AL5 | REDWOOD | 996.2 | 4.56 | 61 | 41.04 | 293.88 | 2751.454664 | 0.0321 |

| Note:The outermost layer is twisted to the right (Z). | ||||||||