+86 13777722188

+86 13777722188

01

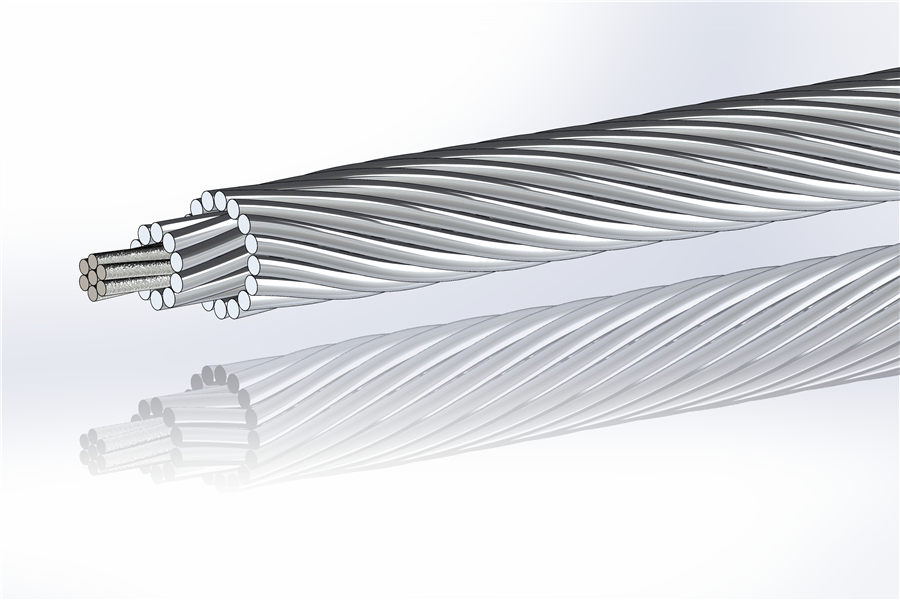

IEC 61089 AACSR Steel Core Aluminum Alloy Conductor

Product advantage

Steel-Cored Aluminum Alloy Stranded Wire: The Preferred Choice for Power Transmission

In overhead power lines, steel-cored aluminum alloy stranded wire stands out as an ideal solution for power transmission and distribution projects, thanks to its dual advantages of "high strength + excellent conductivity," providing stable, efficient, and durable core support for electricity transmission.

1. A Perfect Blend of Strength and Toughness for Complex Environments

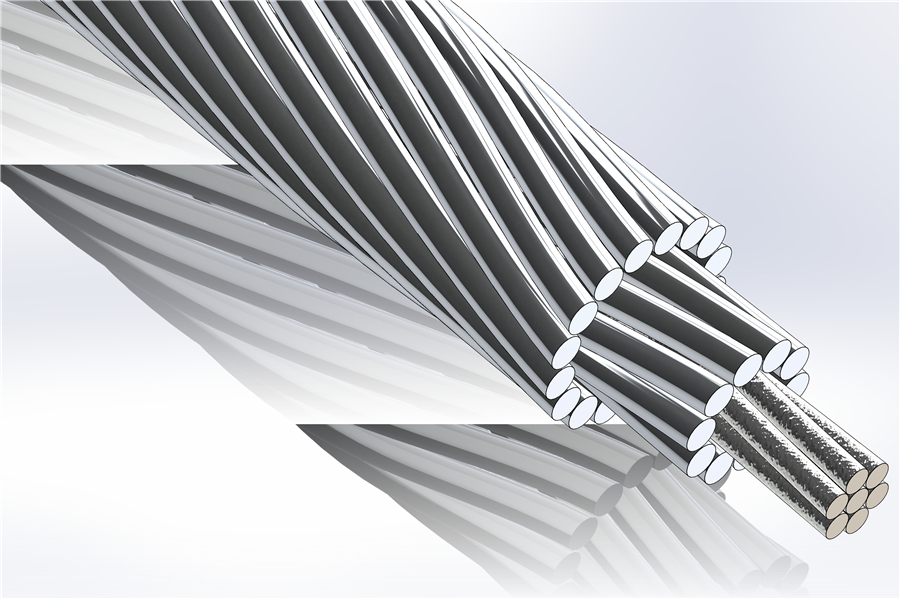

- With high-strength steel wires as the core, the conductor boasts exceptional tensile strength and fatigue resistance, easily handling harsh conditions such as long-span crossings, strong winds, and ice/snow. It minimizes line sag issues, reducing the difficulty of erection and maintenance.

- The outer aluminum alloy strands combine metal toughness with structural stability, offering superior corrosion resistance and aging resistance. This extends the conductor's service life and lowers long-term operational costs.

2. Excellent Conductivity for Higher Transmission Efficiency

Aluminum alloy materials retain conductivity close to pure aluminum while ensuring strength. Compared to traditional steel-cored aluminum strands, they enhance current-carrying capacity under the same cross-section, reduce line losses, and enable more efficient, energy-saving power transmission—ideal for medium and high-voltage long-distance networks.

3. Lightweight Design to Reduce Project Costs

Compared to all-steel conductors or other heavy-duty alternatives, steel-cored aluminum alloy strands meet strength requirements while being lighter overall. This reduces tower load pressure, cuts infrastructure costs, simplifies erection processes, boosts construction efficiency, and shortens project cycles.

4. Outstanding Cost Performance: Balancing Performance and Economy

Considering material properties, construction difficulty, service life, and energy loss, steel-cored aluminum alloy strands achieve the optimal balance of "strength, conductivity, and cost." They overcome the weakness of insufficient strength in pure aluminum wires while being more economical than all-steel conductors—providing enterprises with reliable support for "efficient transmission + cost control" in power projects.

From urban power grid upgrades to cross-regional transmission projects, steel-cored aluminum alloy stranded wire, with its stable performance and wide applicability, remains the cost-effective choice for energy transmission, safeguarding efficient power delivery.

Product application

Steel-Cored Aluminum Alloy Conductors: A Mainstay of Power Transmission Across Diverse Scenarios

With its integrated advantages of "high strength, excellent conductivity, and environmental resistance," steel-cored aluminum alloy conductors serve as a key player in power transmission across multiple fields, delivering tailored solutions for various scenarios.

1. Core Choice for Medium and High-Voltage Transmission Lines

In 110kV to 500kV medium and high-voltage networks, steel-cored aluminum alloy conductors excel as the "main arteries" connecting substations and regional grids. Particularly in urban peripheries and suburban areas, they adapt to complex wiring demands in densely populated zones, balancing transmission efficiency with safety and stability.

2. Reliable Support for Long-Span Crossings

When spanning natural barriers (rivers, valleys, mountains) or critical transportation routes (expressways, railways), the high strength of these conductors reduces the need for excessive pylons, mitigates sag issues caused by long spans, and ensures stable operation under strong winds, temperature fluctuations, and other harsh conditions. They are widely used in river-crossing transmission lines and mountainous overhead projects.

3. Upgrades and Renovations of Urban and Rural Power Grids

In projects involving the renovation of aging grids or capacity expansion in urban and rural areas, their lightweight design simplifies construction and retrofitting. Additionally, their corrosion and aging resistance reduces long-term maintenance needs, making them ideal for complex environments such as dusty rural areas, humid regions, and coastal areas with high salt spray—driving efficiency improvements in grid performance.

4. Efficient Carriers for New Energy Grid Integration

As wind, photovoltaic, and other new energy projects scale up, steel-cored aluminum alloy conductors meet the high-capacity, long-distance grid integration needs of renewable energy plants. Their excellent conductivity minimizes power loss, ensuring stable access of clean energy to the main grid.

5. Power Supply for Industrial and Special Fields

In large industrial parks, mines, ports, and other industrial settings, these conductors withstand continuous high-current operation while resisting corrosion and vibration in industrial environments—guaranteeing uninterrupted power supply for production.

From urban to rural areas, from conventional grids to new energy sectors, steel-cored aluminum alloy conductors, with their versatile adaptability and stable performance, stand as the backbone of power transmission, underpinning the development of modern energy systems.

(AACSR)IEC 61089 Aluminum Alloy Conductor Steel Reinforced(AACSR)

| Nominal Area | Sectional Area | Wire Diameter&Stranding | Diameter of Conductor | Linear Mass | Rated Strngth | Max.D.C. Resistance at 20℃ Ω/km | |||||

| Aluminum alloy | Steel | Total | Aluminum alloy | Steel | |||||||

| mm² | mm² | mm² | mm² | mm | No | mm | No | mm | kg/km | kN | Ohms/km |

| 26 | 18.4 | 3.07 | 21.5 | 1.98 | 6 | 1.98 | 1 | 5.93 | 74.8 | 9.02 | 1.7934 |

| 25 | 28.8 | 4.80 | 33.6 | 2.47 | 6 | 2.47 | 1 | 7.41 | 116.3 | 13.96 | 1.1478 |

| 40 | 46.0 | 7.67 | 53.7 | 3.13 | 6 | 3.13 | 1 | 9.38 | 186.8 | 22.02 | 0.7174 |

| 63 | 72.5 | 12.1 | 84.6 | 3.92 | 6 | 3.92 | 1 | 11.8 | 293.0 | 34.68 | 0.4555 |

| 100 | 115 | 6.39 | 121 | 2.85 | 18 | 2.85 | 1 | 14.3 | 366.0 | 41.24 | 0.2880 |

| 125 | 144 | 7.99 | 152 | 3.19 | 18 | 3.19 | 1 | 16.0 | 458.6 | 51.23 | 0.2304 |

| 125 | 144 | 23.4 | 167 | 2.65 | 26 | 2.06 | 7 | 16.8 | 579.4 | 69.86 | 0.2310 |

| 160 | 184 | 10.2 | 194 | 3.61 | 18 | 3.61 | 1 | 18.0 | 587.3 | 65.58 | 0.1800 |

| 160 | 184 | 30.0 | 214 | 3.00 | 26 | 2.34 | 7 | 19.0 | 743.0 | 88.52 | 0.1805 |

| 200 | 230 | 12.8 | 243 | 4.04 | 18 | 4.04 | 1 | 20.2 | 735.6 | 81.97 | 0.1440 |

| 200 | 230 | 37.5 | 268 | 3.36 | 26 | 2.61 | 7 | 21.3 | 931.0 | 110.64 | 0.1444 |

| 250 | 288 | 28.3 | 316 | 4.08 | 22 | 2.27 | 7 | 23.1 | 1016.6 | 117.09 | 0.1154 |

| 250 | 288 | 46.9 | 335 | 3.75 | 26 | 2.92 | 7 | 23.8 | 1161.5 | 138.31 | 0.1155 |

| 315 | 383 | 25.1 | 408 | 3.20 | 45 | 2.14 | 7 | 25.8 | 1198.0 | 136.28 | 0.0917 |

| 315 | 383 | 59.0 | 442 | 4.21 | 26 | 3.28 | 7 | 26.7 | 1464.4 | 171.90 | 0.0917 |

| 400 | 460 | 31.8 | 492 | 3.61 | 45 | 2.41 | 7 | 28.9 | 1523.8 | 172.10 | 0.0722 |

| 400 | 460 | 59.7 | 520 | 3.29 | 54 | 3.29 | 7 | 29.7 | 1736.9 | 201.46 | 0.0723 |

| 450 | 518 | 35.8 | 554 | 3.83 | 45 | 2.55 | 7 | 30.6 | 1713.7 | 193.61 | 0.0642 |

| 450 | 518 | 67.1 | 585 | 3.49 | 54 | 3.49 | 7 | 31.5 | 1954.5 | 226.64 | 0.0643 |

| 500 | 575 | 39.8 | 615 | 4.04 | 45 | 2.69 | 7 | 32.3 | 1906.8 | 215.12 | 0.0578 |

| 500 | 575 | 74.6 | 650 | 3.68 | 54 | 3.68 | 7 | 33.2 | 2173.1 | 251.82 | 0.0578 |

| 560 | 645 | 44.6 | 689 | 4.27 | 45 | 2.85 | 7 | 34.2 | 2131.8 | 240.93 | 0.0516 |

| 560 | 645 | 81.6 | 726 | 3.90 | 54 | 2.34 | 19 | 35.1 | 2425.7 | 283.21 | 0.0516 |

| 630 | 725 | 31.3 | 756 | 3.58 | 72 | 2.39 | 7 | 35.8 | 2250.4 | 249.62 | 0.0459 |

| 630 | 725 | 91.8 | 817 | 4.13 | 54 | 2.48 | 19 | 37.2 | 2721.4 | 318.61 | 0.0459 |

| 710 | 817 | 35.3 | 852 | 3.80 | 72 | 2.53 | 7 | 38.0 | 2534.0 | 281.32 | 0.0407 |

| 710 | 817 | 104 | 921 | 4.39 | 54 | 2.63 | 19 | 39.5 | 3071.0 | 359.98 | 0.0407 |

| 800 | 921 | 39.8 | 961 | 4.04 | 72 | 2.69 | 7 | 40.4 | 2864.2 | 316.98 | 0.0361 |

| 800 | 921 | 76.7 | 997 | 3.74 | 84 | 3.74 | 7 | 41.1 | 3156.3 | 356.03 | 0.0362 |

| 900 | 1036 | 44.8 | 1081 | 4.28 | 72 | 2.85 | 7 | 42.8 | 3214.7 | 356.6 | 0.0321 |

| 900 | 1036 | 86.3 | 1122 | 3.96 | 84 | 3.96 | 7 | 43.6 | 3538.6 | 400.53 | 0.0322 |

| 1000 | 1151 | 93.7 | 1245 | 4.18 | 84 | 2.51 | 19 | 45.9 | 3926.6 | 446.37 | 0.0289 |

| 1120 | 1289 | 105 | 1394 | 4.42 | 84 | 2.65 | 19 | 48.6 | 4387.8 | 499.93 | 0.0258 |