+86 13777722188

+86 13777722188

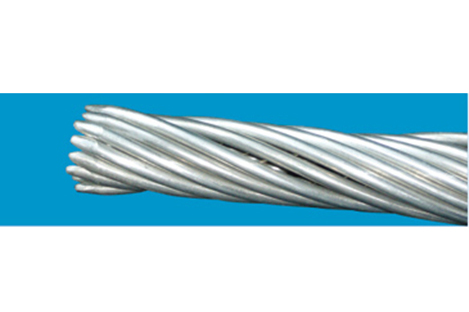

Preformed Guard Wires (SHL)

Preformed Guard Wires (SHL) Features

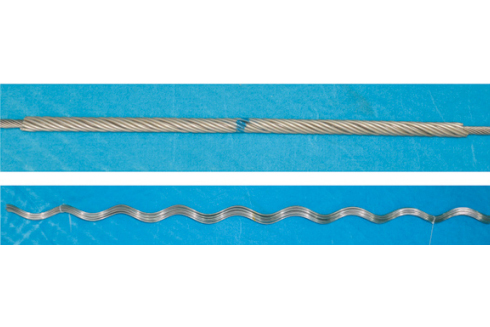

1. Minimal Abrasion: The guard wires and pre-guard wires are tightly twisted, avoiding direct abrasion between the conductor and external objects, thus minimizing conductor wear.

2. Anti-loosening & Anti-corrosion: The preformed wires have a strong gripping property, ensuring long-term stability without loosening.

3. Superior Corrosion Resistance: The wires undergo anti-rust treatment, guaranteeing the corrosion resistance of the entire line.

4. Easy Installation: No special tools are needed; installation can be quickly and easily completed on-site by hand, even by a single person.

5. Guaranteed Installation Quality: No specialized training is required—inspection can be done visually. The design is simple and aesthetically pleasing.

6. High Versatility: Compatible with a wide range of hardware fittings.

Maintenance Instructions

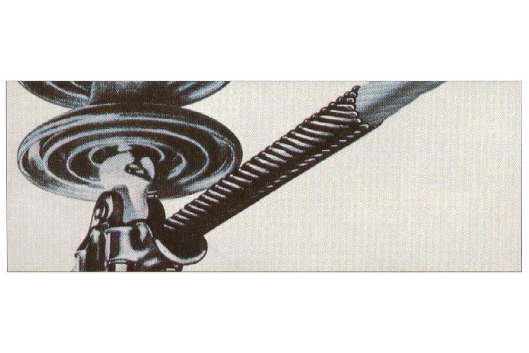

When less than 25% of the outermost aluminum strands in Aluminum Conductor Steel Reinforced (ACSR) or aluminum stranded conductors are broken, repair strips can be used to restore 100% of the mechanical and electrical properties.

When 25% – 50% of the outermost aluminum strands in ACSR or aluminum stranded conductors are broken, preformed guard wires can be used to restore 100% of the mechanical and electrical properties.

Armor Rods Series

Selection Table of Preformed Armor Rods for Steel - Reinforced Aluminum Stranded Wire

| Company Product Model | Industry Standard Model | Applicable Conductor Type (GB1179 - 83)Steel - Reinforced Aluminum Stranded Wire LGJ/LGJF | Reference Length (mm) | Wire Diameter (mm) | Wire Weight (Kg) | Color Code | |

| Conductor Model | Outer Diameter | ||||||

| HL - 35/6 | HL - 35/6 | Jun-35 | 8.16 | 1100 | 3 | 0.22 | Red |

| HL - 50/8 | HL - 50/8 | Aug-50 | 9.36 | 1270 | 3 | 0.3 | Black |

| HL - 95/15 | HL - 95/15 | 95/15 | 13.37 | 1400 | 3.6 | 0.55 | Yellow |

| HL - 95/20 | HL - 95/20 | 95/20 | 13.57 | 0.58 | Yellow - green | ||

| HL - 95/55 | HL - 95/55 | 95/55 | 16.8 | 1500 | 3.6 | 0.7 | Red |

| HL - 120/7 | HL - 120/7 | 120/7 | 14.5 | 1400 | 3.6 | 0.58 | White |

| HL - 120/20 | HL - 120/20 | 120/20 | 15.07 | 0.63 | Blue - white | ||

| HL - 120/25 | HL - 120/25 | 120/25 | 15.74 | 4.6 | 0.63 | Brown | |

| HL - 150/8 | HL - 150/8 | 150/8 | 16 | 1800 | 3.6 | 0.75 | Red |

| HL - 150/20 | HL - 150/20 | 150/20 | 16.67 | 1500 | 0.7 | Red | |

| HL - 150/25 | HL - 150/25 | 150/25 | 17.1 | 3.6 | 0.75 | Blue | |

| HL - 150/35 | HL - 150/35 | 150/35 | 17.9 | Blue - green | |||

| HL - 185/10 | HL - 185/10 | 185/10 | 18.5 | 1.28 | Yellow | ||

| HL - 185/25 | HL - 185/25 | 185/25 | 18.8 | 1800 | 1.31 | White | |

| HL - 185/30 | HL - 185/30 | 185/30 | 19.38 | 1.3 | Blue - green | ||

| HL - 185/45 | HL - 185/45 | 185/45 | 19.4 | 4.6 | White | ||

| HL - 210/10 | HL - 210/10 | 210/10 | 19.9 | 1.3 | White | ||

| HL - 210/25 | HL - 210/25 | 210/25 | 20.38 | 1.31 | Brown | ||

| HL - 210/50 | HL - 210/50 | 210/50 | 20.86 | Purple | |||

| HL - 240/30 | HL - 240/30 | 240/30 | 21.6 | 1900 | 4.6 | 1.53 | Blue |

| HL - 240/55 | HL - 240/55 | 240/55 | 22.6 | Blue - green | |||

| HL - 300/15 | HL - 300/15 | 300/15 | 23.01 | 2000 | 6.3 | 2.26 | Black |

| HL - 300/20 | HL - 300/20 | 300/20 | 23.43 | 2.44 | White | ||

| HL - 300/25 | HL - 300/25 | 300/25 | 23.76 | ||||

| HL - 300/50 | HL - 300/50 | 300/50 | 24.26 | 2.46 | Brown | ||

| HL - 300/70 | HL - 300/70 | 300/70 | 25.2 | 2.48 | Blue | ||

| HL - 400/20 | HL - 400/20 | 400/20 | 26.91 | 2200 | 6.3 | 2.98 | Blue - green |

| HL - 400/35 | HL - 400/35 | 400/35 | 26.73 | 3 | Green | ||

| HL - 400/50 | HL - 400/50 | 400/50 | 27.82 | Yellow | |||

| HL - 400/95 | HL - 400/95 | 400/95 | 28.14 | 3.1 | White | ||

| HL - 500/35 | HL - 500/35 | 500/35 | 30 | 2500 | 6.3 | 3.77 | Brown |

| HL - 500/45 | HL - 500/45 | 500/45 | 30.3 | Orange | |||

| HL - 500/65 | HL - 500/65 | 500/65 | 30.6 | Purple | |||

| HL - 630/45 | HL - 630/45 | 630/45 | 33.4 | 7.8 | 5.1 | Yellow - green | |

| HL - 630/80 | HL - 630/80 | 630/80 | 34.32 | 5.4 | Black | ||

| HL - 630/100 | HL - 630/100 | 630/100 | 35.42 | 6 | Red | ||

| HL - 800/55 | HL - 800/55 | 800/55 | 38.4 | 7.8 | 6 | Red | |

| HL - 800/70 | HL - 800/70 | 800/70 | 38.58 | 6.1 | Blue | ||

| HL - 800/100 | HL - 800/100 | 800/100 | 38.98 | 6.2 | Blue - green | ||

Selection Table of Preformed Armor Rods for Aluminum Stranded Wire

| Company Product Model | Applicable Conductor Diameter Range (mm) | Aluminum Stranded Wire LJ(GB1179 - 83) | Reference Length (mm) | Wire Weight (Kg) | Color Code | |

| Minimum | Maximum | |||||

| HL - 50L | 8.81 | 9.3 | 50 | 1210 | 0.4 | Green |

| HL - 70L | 10.52 | 11.07 | 70 | 1320 | 0.4 | Brown |

| HL - 95L | 12.47 | 12.23 | 95 | 1370 | 0.6 | Green |

| HL - 120L | 14.01 | 14.86 | 120 | 1520 | 0.8 | Red |

| HL - 150L | 15.4 | 16 | 150 | 1500 | 1 | Purple |

| HL - 185L | 17.3 | 17.86 | 185 | 1730 | 1.3 | Blue |

| HL - 210L | 17.87 | 18.8 | 210 | 1830 | 1.5 | Green |

| HL - 240L | 20.69 | 21.46 | 240 | 1930 | 2 | Red |

| HL - 300L | 21.47 | 23.04 | 300 | 1980 | 2.2 | Blue |

| HL - 400L | 25.82 | 26.29 | 400 | 2380 | 4.2 | Brown |

Selection Table of Preformed Armor Rods for Aluminum - Clad Steel Stranded Wire

| Company Product Model | Applicable Conductor Diameter Range (mm) | Reference Length (mm) | Wire Weight (Kg) | Color Code | |

| Minimum | Maximum | ||||

| HL - 0841LB | 3.43 | 3.64 | 870 | 0.1 | Blue |

| HL - 0871LB | 3.65 | 3.87 | 910 | 0.2 | Black |

| HL - 0842LB | 3.88 | 4.06 | 970 | 0.2 | Red |

| HL - 0891LB | 4.06 | 4.28 | 970 | 0.2 | Yellow |

| HL - 0841LB | 4.29 | 4.54 | 1020 | 0.2 | Brown |

| HL - 0871LB | 4.55 | 4.79 | 1020 | 0.2 | Green |

| HL - 0891LB | 4.8 | 4.97 | 1020 | 0.2 | Blue |

| HL - 0827LB | 4.98 | 5.27 | 1020 | 0.2 | Black |

| HL - 0831LB | 5.28 | 5.53 | 1020 | 0.2 | Blue |

| HL - 0873LB | 5.54 | 5.73 | 1020 | 0.2 | Green |

| HL - 0891LB | 5.74 | 6.01 | 1020 | 0.2 | Black |

| HL - 0841LB | 6.02 | 6.34 | 1020 | 0.4 | Yellow |

| HL - 0870LB | 6.35 | 6.65 | 1070 | 0.5 | Red |

| HL - 0891LB | 6.71 | 7.05 | 1070 | 0.5 | Blue |

| HL - 0791LB | 7.06 | 7.51 | 1120 | 0.5 | Red |

| HL - 0771LB | 7.52 | 7.99 | 1170 | 0.5 | Black |

| HL - 0871LB | 8.0 | 8.37 | 1230 | 0.6 | Green |

| HL - 0894LB | 8.48 | 8.96 | 1270 | 0.6 | Yellow |

| HL - 0861LB | 8.77 | 9.46 | 1270 | 0.8 | Blue |

| HL - 0971LB | 9.77 | 9.97 | 1270 | 0.8 | Red |

| HL - 0898LB | 9.98 | 10.58 | 1330 | 0.9 | Brown |

| HL - 1041LB | 10.39 | 10.81 | 1370 | 0.9 | Red |

| HL - 1081LB | 10.82 | 11.41 | 1420 | 1.0 | Black |

| HL - 1210LB | 11.45 | 12.11 | 1420 | 1.2 | Green |

| HL - 1281LB | 12.12 | 12.82 | 1420 | 1.2 | Blue |

| HL - 1351LB | 12.83 | 13.58 | 1470 | 1.5 | Red |

| HL - 1431LB | 13.59 | 14.35 | 1520 | 1.8 | Yellow |

| HL - 1501LB | 14.36 | 15.05 | 1520 | 2.1 | Brown |

| HL - 1581LB | 15.06 | 15.89 | 1530 | 2.1 | Pink |

| HL - 1691LB | 15.9 | 16.91 | 1570 | 2.5 | Blue |

| HL - 1092LB | 16.92 | 17.82 | 1570 | 2.7 | Green |

| HL - 1783LB | 17.83 | 18.69 | 1620 | 3.0 | Yellow |

| HL - 1891LB | 18.69 | 19.5 | 1620 | 3.0 | Blue |

| HL - 1981LB | 19.51 | 20.08 | 1670 | 3.3 | Black |

| HL - 2158LB | 20.09 | 21.38 | 1720 | 3.4 | Red |

| HL - 2182LB | 21.39 | 21.82 | 1780 | 3.8 | Yellow |

| HL - 2381LB | 22.63 | 23.89 | 1830 | 4.1 | Brown |

| HL - 2591LB | 23.9 | 25.29 | 1880 | 4.3 | Green |

| HL - 2580LB | 25.3 | 26.8 | 1930 | 5.4 | Red |

Note: This table only lists some products. For other specification products, please consult the company.

Selection Table of Anti - Corona Preformed Armor Rods(SFHL) (Above 345 kV)

| Company Product Model | Applicable Conductor Diameter Range (mm) | teel - Reinforced Aluminum Stranded Wire LGJ/LGJF; Aluminum Stranded Wire LJ | Reference Length (mm) | Wire Weight (Kg) | Color Code | |

| Minimum | Maximum | |||||

| FHL - 300/20 | 23.05 | 23.6 | 300/20 | 2030 | 2.5 | Green |

| FHL - 300/25 | 23.61 | 24.79 | 300/25 | 2230 | 2.7 | White |

| FHL - 300/40 | 300/40 | |||||

| FHL - 300/50 | 24.8 | 25.81 | 300/50 | 2340 | 2.5 | Yellow |

| FHL - 400/1 | 25.82 | 26.29 | 300/70; | 2380 | 4.2 | Brown |

| FHL - 400/20 | 26.3 | 27.03 | 400/20 | 2430 | 4.2 | Blue |

| FHL - 400/25 | 400/25 | |||||

| FHL - 400/35 | 27.04 | 27.89 | 400/35 | 2430 | 4.2 | Green |

| FHL - 400/50 | 400/50 | |||||

| FHL - 400/65 | 27.9 | 28.93 | 400/65 | 4.7 | Orange | |

| FHL - 400/95 | 28.94 | 29.49 | 400/95 | 4.8 | Purple | |

| FHL - 500/35 | 500/35 | 5.2 | Red | |||

| FHL - 500/45 | 29.5 | 30.68 | 500/45 | |||

| FHL - 630/45 | 30.29 | 32.23 | 630/45; | 6.1 | Black | |

| FHL - 630/65 | 36.24 | 33.71 | 630/65 | 6.1 | White | |

| FHL - 630/55 | 33.72 | 35.31 | 630/55 | 2540 | 6.3 | Yellow |

Note: This table only lists some products. For other specification products, please consult the company.

Type Selection Table for Preformed Armor Rods for Copper - Clad Steel Stranded Wires

| Serial No. | Company Product Model | Applicable Copper Conductor Cross - sectional Area (mm) | Length (mm) | Material | Remarks |

| 1 | THL - 50 2000 | 50 | 2000 | Copper - Clad Steel Wire | |

| 2 | THL - 70 2000 | 70 | 2000 | Copper - Clad Steel Wire | |

| 3 | THL - 95 2000 | 95 | 2000 | Copper - Clad Steel Wire | |

| 4 | THL - 100 2000 | 100 | 2000 | Copper - Clad Steel Wire | |

| 5 | THL - 120 2000 | 120 | 2000 | Copper - Clad Steel Wire |

Selection Table of Preformed Armor Rods for Steel Stranded Wire

| Company Product Model (Single - support/Composite - support) | Applicable Conductor Diameter Range (mm) | Applicable Conductor Type (GB1200 - 88)Steel Strand GJ | Reference Length (mm) | Wire Weight (Kg) | Color Code | |

| Minimum | Maximum | |||||

| HL - 25G | 6.2 | 6.58 | 25 | 1020 | 0.3 | Yellow |

| HL - 35G | 7.37 | 7.82 | 35 | 1110 | 0.4 | Red |

| HL - 50G | 8.81 | 9.47 | 50 | 1210 | 0.6 | Orange |

| HL - 70G | 10.52 | 11.07 | 70 | 1320 | 0.9 | Green |

| HL - 80G | 11.09 | 11.76 | 80 | 1371 | 1.2 | Yellow |

| HL - 90G | 11.77 | 12.46 | 90 | 1400 | 1.3 | Brown |

| HL - 95G | 12.47 | 12.23 | 95 | - | - | - |

| HL - 100G | 12.47 | 12.23 | 100 | 1420 | 1.4 | Blue |