+86 13777722188

+86 13777722188

Preformed Splicing Strips (SJL)

Instructions for Use

① For steel-cored aluminum stranded wires, splicing strips restore the aluminum conductor’s strength but not the steel core’s. If there are signs of steel core damage, full-tension splicing strips should be used.

② All conductors (whether new or used) must be thoroughly cleaned and polished to remove the oxide layer until a glossy surface is exposed before installing splicing strips. High-quality, conductor-matched conductive grease must be applied to the conductor surface before installation.

③ Splicing on the conductor splicing strips is allowed. Before installing splicing clips:

Thoroughly polish the conductor and apply conductive grease.

Fully polish the outer surface of the splicing strips to remove any oxide layers or adhesive.

Apply conductive grease to the splicing area of the strips as well.

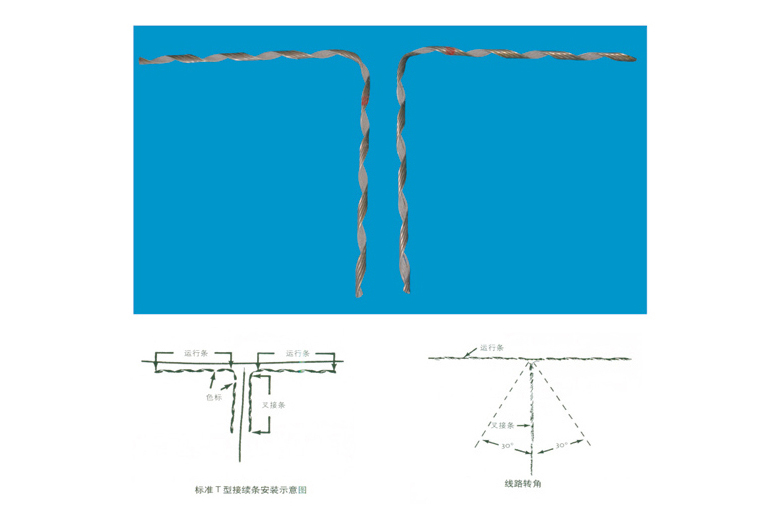

④ When installing the splicing strip with its midpoint aligned to the damage point on the conductor:

The distance from the end of the splicing strip to the end of already installed preformed guard strips or preformed short guard strips must be ≥ 152mm.

This type of splicing strip (and its repair function) can only be used if the conductor’s damage point is at a support point or beyond the nearest damage point.

(Illustration description:

Support Point

Guard Strips or Short Guard Strips

Splicing Strip

Nearest Damage Point

Distance: >152mm )

⑤ Preformed conductor splicing strips are designed for specific scenarios and can only be used once. Never reuse or modify the product under any circumstances.

Preformed Armor Rods for Aluminum Conductor Steel Reinforced (ACSR) (SBL)

| Company Product Model | Industry Standard Model | Applicable Conductor Model | Outer Diameter of Conductor Structure (mm) | Reference Clamp Length (mm) | Single Wire Diameter (mm) | Clamp Weight (kg) | Color Code |

| (referring to GB/T 1179-83/GB/T 1179-2017) | |||||||

| HL-35/6 | HL-35/6 | Jun-35 | 8.16 | 1100 | 3 | 0.22 | Red |

| HL-50/8 | HL-50/8 | Aug-50 | 8.16 | 1270 | 3 | 0.3 | Red |

| HL-95/15 | HL-95/15 | 95/15 | 13.41 | 1270 | 3.6 | 0.3 | Yellow |

| HL-95/20 | HL-95/20 | 95/20 | 13.67 | 1400 | 3.6 | 0.55 | Yellow |

| HL-95/55 | HL-95/55 | 95/55 | 16.8 | 1500 | 3.6 | 0.7 | Red |

| HL-120/7 | HL-120/7 | 120/7 | 14.4 | - | - | 0.58 | White |

| HL-120/20 | HL-120/20 | 120/20 | 15.07 | 1400 | 3.6 | 0.63 | Brown |

| HL-120/70 | HL-120/70 | 120/70 | 15.74 | - | - | 0.63 | Red |

| HL-150/8 | HL-150/8 | 150/8 | 16 | 1800 | 4.6 | 0.75 | Brown |

| HL-150/20 | HL-150/20 | 150/20 | 16.47 | 1500 | 3.6 | 0.7 | Red |

| HL-150/25 | HL-150/25 | 150/25 | 17.1 | 1500 | 3.6 | 0.75 | Blue |

| HL-150/35 | HL-150/35 | 150/35 | 17.5 | - | - | - | - |

| HL-185/10 | HL-185/10 | 185/10 | 18 | - | - | 1.28 | Yellow |

| HL-185/25 | HL-185/25 | 185/25 | 18.9 | - | - | 1.3 | White |

| HL-185/30 | HL-185/30 | 185/30 | 18.58 | - | - | 1.31 | Brown |

| HL-185/45 | HL-185/45 | 185/45 | 19.6 | 1800 | 4.6 | 1.3 | White |

| HL-210/10 | HL-210/10 | 210/10 | 19.98 | - | - | 1.31 | Pink |

| HL-210/25 | HL-210/25 | 210/25 | 20.28 | - | - | - | - |

| HL-210/35 | HL-210/35 | 210/35 | 20.86 | - | - | - | - |

| HL-240/08 | HL-240/08 | 240/08 | 21.46 | 1900 | 4.6 | 1.53 | Blue |

| HL-240/30 | HL-240/30 | 240/30 | 22 | - | - | - | - |

| HL-240/55 | HL-240/55 | 240/55 | 22.46 | - | - | - | Green |

| HL-300/15 | HL-300/15 | 300/15 | 23.01 | 2000 | 6.3 | 2.26 | Black |

| HL-300/20 | HL-300/20 | 300/20 | 23.43 | 2000 | 6.3 | 2.44 | White |

| HL-300/25 | HL-300/25 | 300/25 | 23.76 | 2000 | 6.3 | 2.46 | Brown |

| HL-300/50 | HL-300/50 | 300/50 | 24.26 | 2000 | 6.3 | 2.48 | Pink |

| HL-300/70 | HL-300/70 | 300/70 | 25.2 | 2000 | 6.3 | 2.9 | Blue |

| HL-400/20 | HL-400/20 | 400/20 | 26.81 | 2200 | 6.3 | 3 | Green |

| HL-400/35 | HL-400/35 | 400/35 | 26.92 | 2200 | 6.3 | 3.1 | Green-Yellow |

| HL-400/50 | HL-400/50 | 400/50 | 27.14 | 2200 | 6.3 | 3.1 | White |

| HL-400/95 | HL-400/95 | 400/95 | 28 | 2500 | 6.3 | 3.77 | Brown |

| HL-500/35 | HL-500/35 | 500/35 | 30 | 2500 | 6.3 | - | - |

| HL-500/45 | HL-500/45 | 500/45 | 30 | 2500 | 6.3 | - | - |

| HL-630/45 | HL-630/45 | 630/45 | 33.6 | 2500 | 7.8 | 5.1 | Purple |

| HL-630/55 | HL-630/55 | 630/55 | 34.23 | 2500 | 7.8 | 5.4 | Black |

| HL-630/80 | HL-630/80 | 630/80 | 38.8 | 2500 | 7.8 | 5.4 | Black |

| HL-800/55 | HL-800/55 | 800/55 | 38.4 | 2500 | 7.8 | 6.1 | Red |

| HL-800/70 | HL-800/70 | 800/70 | 38.98 | 2500 | 7.8 | 6.1 | Blue |

| HL-800/100 | HL-800/100 | 800/100 | 38.98 | 2500 | 7.8 | 12.28 | Blue |

Selection Table of Preformed Armor Rods for Aluminum Stranded Wire Connection

| Company product model | Industry standard model | Applicable conductor diameter (mm) | Applicable conductor type (GB1179 - 83) | Industry Sta ndard Model | Reference Clamp Length (mm) | Clamp Weight (kg) | Color Code |

| Minimum | Maximum | ||||||

| JLD - 16L | 4.91 | 5.13 | 16 | 558 | 0.08 | Blue | |

| JLD - 25L | 6.26 | 6.53 | 25 | 660 | 0.1 | Blue - orange | |

| JLD - 35L | 7.35 | 7.57 | 35 | 710 | 0.12 | Purple | |

| JLD - 50L | 8.94 | 9.32 | 50 | 860 | 0.19 | Purple | |

| JLD - 70L | 10.22 | 10.8 | 70 | 1020 | 0.32 | Brown | |

| JLD - 95L | JL - 95LJ | 12.54 | 12.78 | 95 | 1168 | 0.44 | Pink |

| JLD - 120L | JL - 120LJ | 13.83 | 14.4 | 120 | 1321 | 0.6 | Red |

| JLD - 150L | JL - 150LJ | 15.72 | 16.36 | 150 | 1792 | 1.05 | Yellow |

| JLD - 185L | JL - 185LJ | 17.05 | 17.78 | 185 | 1778 | 1.24 | Yellow - green |

| JLD - 210L | JL - 210LJ | 18.53 | 19.3 | 210 | 2007 | 1.9 | Black |

| JLD - 240L | JL - 240LJ | 19.91 | 20.12 | 240 | 2108 | 2.18 | Purple |

| JLD - 300L | JL - 300LJ | 21.62 | 22.5 | 300 | 2515 | 2.84 | Blue - orange |

| JLD - 400L | JL - 400LJ | 25.62 | 26.67 | 400 | 3073 | 4.56 | Green |

| JLD - 500L | JL - 500LJ | 27.71 | 30.05 | 500 | 3451 | 6.5 | Red |

Note: Meanings of letters and numbers in the models in the table: J - Armor rod; L - Spiral preformed armor rod; D - Wire, number - Product specification; LJ - Aluminum stranded wire.

Selection Table of Preformed Armor Rods for Steel - Reinforced Aluminum Stranded Wire Repair

| Company Product Model | Industry Standard Model | Applicable Conductor Type (GB1179 - 83)Steel - Reinforced Aluminum Stranded Wire LGJ, LGJF | Reference Length (mm) | Wire Diameter (mm) | Wire Weight (Kg) | Color Code | |

| Conductor Model | Outer Diameter | ||||||

| BL - 70/10 | BL - 70/10 | Oct-70 | 11.4 | 420 | 3.6 | 0.14 | Red |

| BL - 95/15 | BL - 95/15 | 95/15 | 13.41 | 0.18 | Yellow | ||

| BL - 95/20 | BL - 95/20 | 95/20 | 13.57 | 0.18 | Black | ||

| BL - 95/55 | BL - 95/55 | 95/55 | 16.8 | 450 | 0.2 | Red | |

| BL - 120/7 | BL - 120/7 | 120/7 | 14.2 | 3.6 | 0.2 | White | |

| BL - 120/20 | BL - 120/20 | 120/20 | 15.07 | 0.22 | Blue - white | ||

| BL - 120/25 | BL - 120/25 | 120/25 | 15.74 | 0.22 | Brown | ||

| BL - 120/70 | BL - 120/70 | 120/70 | 18 | 480 | 0.36 | Red | |

| BL - 150/8 | BL - 150/8 | 150/8 | 16 | 3.6 | 0.32 | Yellow - green | |

| BL - 150/20 | BL - 150/20 | 150/20 | 16.77 | 0.24 | Blue | ||

| BL - 150/25 | BL - 150/25 | 150/25 | 17.1 | 0.24 | Blue | ||

| BL - 150/35 | BL - 150/35 | 150/35 | 17.9 | 560 | 0.24 | Yellow | |

| BL - 185/10 | BL - 185/10 | 185/10 | 18.5 | 4.6 | 0.4 | Blue - green | |

| BL - 185/20 | BL - 185/20 | 185/20 | 18.8 | 0.4 | White | ||

| BL - 185/25 | BL - 185/25 | 185/25 | 19.3 | 0.41 | White | ||

| BL - 185/45 | BL - 185/45 | 185/45 | 19.4 | 600 | 0.41 | Brown | |

| BL - 210/10 | BL - 210/10 | 210/10 | 19.7 | 4.6 | 0.42 | White | |

| BL - 210/25 | BL - 210/25 | 210/25 | 20.38 | 0.42 | Purple | ||

| BL - 210/55 | BL - 210/55 | 210/55 | 21.86 | 0.45 | Brown | ||

| BL - 240/30 | BL - 240/30 | 240/30 | 21.6 | 650 | 4.6 | 0.53 | Blue |

| BL - 240/40 | BL - 240/40 | 240/40 | 22.6 | Blue - green | |||

| BL - 300/15 | BL - 300/15 | 300/15 | 23.4 | 6.3 | 1.22 | Green | |

| BL - 300/25 | BL - 300/25 | 300/25 | 23.73 | 1000 | Black | ||

| BL - 300/40 | BL - 300/40 | 300/40 | 25.24 | 1.33 | White | ||

| BL - 300/50 | BL - 300/50 | 300/50 | 25.7 | 1.3 | Brown | ||

| BL - 300/70 | BL - 300/70 | 300/70 | 27.52 | 1.33 | Blue - orange | ||

| BL - 400/20 | BL - 400/20 | 400/20 | 26.91 | 6.3 | 1.32 | Blue | |

| BL - 400/25 | BL - 400/25 | 400/25 | 26.64 | ||||

| BL - 400/35 | BL - 400/35 | 400/35 | 26.68 | 6.3 | 1.45 | Blue - green | |

| BL - 400/50 | BL - 400/50 | 400/50 | 27.83 | 1.46 | Blue | ||

| BL - 400/65 | BL - 400/65 | 400/65 | 28.14 | 1100 | Yellow | ||

| BL - 400/95 | BL - 400/95 | 400/95 | 30 | 1.5 | Blue - green | ||

| BL - 500/35 | BL - 500/35 | 500/35 | 30 | 1.66 | Brown | ||

| BL - 500/45 | BL - 500/45 | 500/45 | 30.3 | Orange | |||

| BL - 500/65 | BL - 500/65 | 500/65 | 31.6 | 7.8 | Purple | ||

| BL - 630/45 | BL - 630/45 | 630/45 | 33.4 | 1500 | 2.62 | Yellow - green | |

Preformed Armor Rods for Steel - Reinforced Aluminum Stranded Wire Connection

Selection Table of Preformed Armor Rods for Steel - Reinforced Aluminum Stranded Wire Connection

| Company Product Model | Applicable Conductor Diameter (mm) | Steel - Reinforced Aluminum Stranded Wire LGJ/LGJF | Reference Length (mm) | Tensile Load (kN) | Color Code | |

| Minimum | Maximum | |||||

| JLD - 16/2 | 4.59 | 4.67 | 16th of February | 530 | 0.65 | Purple |

| JLD - 16/3 | 5.39 | 5.56 | 16th of March | 530 | 0.65 | Green |

| JLD - 25/4 | 6.88 | 7.11 | 25th of April | 680 | 0.85 | Red |

| JLD - 35/6 | 7.9 | 8.26 | Jun-35 | 740 | 0.11 | Yellow |

| JLD - 50/8 | 8.94 | 9.32 | Aug-50 | 860 | 0.17 | Green |

| JLD - 50/17 | 10.52 | 10.8 | 50/17 | 970 | 0.25 | Brown |

| JLD - 70/10 | 11.28 | 11.73 | Oct-70 | 1020 | 0.35 | Blue |

| JLD - 70/18 | 12.24 | 12.78 | 70/18 | 1168 | 0.42 | Brown |

| JLD - 70/40 | 13.26 | 13.82 | 70/40 | 1300 | 0.6 | Black |

| JLD - 95/15 | 13.83 | 14.4 | 95/15 | 1321 | 0.6 | Red |

| JLD - 120/7 | 14.41 | 15.09 | 120/7 | 550 | 0.87 | Blue |

| JLD - 120/20 | 120/20 | |||||

| JLD - 120/25 | 15.72 | 16.36 | 120/25 | 1792 | 1.65 | Yellow |

| JLD - 150/8 | 16.37 | 17.04 | 150/8 | 1750 | 1.24 | Brown |

| JLD - 150/20 | 17.35 | 17.68 | 150/20 | 1778 | 1.26 | Brown |

| JLD - 150/25 | 17.79 | 18.52 | 150/25 | 1960 | 1.88 | Green |

| JLD - 185/10 | 18.53 | 19.3 | 185/10 | 2007 | 1.84 | Black |

| JLD - 185/30 | 185/30 | |||||

| JLD - 185/40 | 19.31 | 20.12 | 185/40 | 2108 | 2.18 | Purple |

| JLD - 210/25 | 210/25 | 2130 | 2.2 | Red | ||

| JLD - 210/35 | 20.17 | 20.96 | 210/35 | 2180 | 2.26 | Blue |

| JLD - 240/30 | 20.93 | 21.61 | 240/30 | 2515 | 2.84 | Brown |

| JLD - 240/55 | 21.62 | 22.5 | 240/55 | |||

| JLD - 300/15 | 22.51 | 23.6 | 300/15 | 2670 | 3.84 | Brown |

| JLD - 300/20 | 300/20 | |||||

| JLD - 300/25 | 23.61 | 24.59 | 300/25 | 2740 | 4.2 | Brown |

| JLD - 300/40 | 24.6 | 25.6 | 300/40 | 2820 | 4.42 | Yellow |

| JLD - 300/70 | 300/70 | |||||

| JLD - 400/25 | 25.61 | 26.71 | 400/25 | 3073 | 4.81 | Green |

| JLD - 400/35 | 26.68 | 27.67 | 400/35 | 3230 | 5.56 | Black |

| JLD - 400/65 | 27.72 | 28.87 | 400/65 | 3480 | 7.44 | Purple |

| JLD - 400/95 | 28.88 | 30.05 | 400/95 | 3581 | 6.76 | Red |

| JLD - 500/35 | 500/35 | |||||

| JLD - 500/45 | 30.06 | 32.1 | 500/45 | 3630 | 7.85 | Blue |

Selection Table of Preformed Armor Rods for Strength Supplement of Steel Strand Ground Wire Splicing Sleeves

| Company Product Model | Applicable Conductor Diameter (mm) | Applicable Conductor Type (GB1200 - 88) | Splicing Sleeve Model | Maximum Length of Splicing Sleeve (mm) | Reference Length (mm) | Wire Weight (Kg) | |

| Minimum | Maximum | Steel Strand (GJ) | |||||

| JLB - 35G | 7.4 | 8 | 35 | JY - 35G | 300 | 1790 | 0.75 |

| JLB - 50G | 8.7 | 9.1 | 50 | JY - 50G | 240 | 1900 | 0.95 |

| JLB - 70G | 10.5 | 11.1 | 70 | JY - 70G | 290 | 2400 | 2.1 |

| JLB - 80G | 11.4 | 11.8 | 80 | JY - 80G | 260 | 2330 | 1.9 |

| JLB - 100G | 12.9 | 13.3 | 100 | JY - 100G | 320 | 3270 | 4 |

| JLB - 120G | 14 | 14.7 | 120 | 640 | 3520 | 5.4 | |

Selection Table of Preformed Armor Rods for Strength Enhancement of Conductor Splicing Sleeves

| Company Product Model | Applicable Conductor Diameter Range (mm) | Applicable Conductor Type (GB1179 - 83) | Splicing Sleeve Model | Maximum Length of Splicing Sleeve (mm) | Reference Length (mm) | Wire Weight (Kg) | |||

| Minimum | Maximum | Steel - Reinforced Aluminum Stranded Wire LGJ/LGJF | Splicing Sleeve Model | Aluminum Stranded Wire LJ | |||||

| JLB - 3101 | 12.24 | 12.78 | - | - | 95 | JT - 95L | 280 | 1470 | 0.5 |

| JLB - 3103 | 13.26 | 13.82 | 95/15 | JT | - | - | 600 | 2010 | 0.9 |

| JLB - 3104 | 13.83 | 14.4 | 95/20 | JT | - | - | 600 | 2040 | 0.9 |

| JLB - 3106 | 14.41 | 15.09 | 120/20 | JYJTB | - | - | 490 | 2060 | 1.1 |

| JLB - 3107 | 15.72 | 16.36 | 120/25 | JY | 150 | JT/JY - 150L | 430 | 2060 | 1.2 |

| JLB - 3108 | 16.37 | 17.04 | 150/20 | JYJTB | - | - | 470 | 2250 | 1.5 |

| JLB - 3109 | 17.05 | 17.74 | 160/20, 185/35 | JYJTB | 185 | JT/JY - 185L | 570 | 2220 | 1.5 |

| JLB - 3111 | 18.53 | 19.3 | 185/25, 185/30 | JYJTB | 210 | JY - 210L | 540 | 2210 | 2.3 |

| JLB - 3112 | 19.31 | 20.12 | 185/45, 210/25 | JYJTB | 240 | JY - 240L | 570 | 2550 | 2.6 |

| JLB - 3113 | 20.17 | 20.96 | 210/35, 210/50 | JYJTB | - | - | 600 | 2760 | 2.8 |

| JLB - 3114 | 20.93 | 21.61 | 240/30, 240/40 | JYJTB | - | - | 570 | 2830 | 2.7 |

| JLB - 3115 | 21.62 | 22.5 | 240/40, 240/55 | JYJYD | 300 | JY - 300L | 640 | 3090 | 3.4 |

| JLB - 3116 | 22.51 | 23.6 | 300/15, 300/25 | JYJYD | - | - | 580 | 3180 | 4.5 |

| JLB - 3117 | 23.61 | 24.59 | 300/25, 300/40, 300/50 | JYJYD | - | - | 660 | 3410 | 5.2 |

| JLB - 3118 | 24.6 | 25.6 | 300/70 | JYJYD | - | - | 620 | 3570 | 5.6 |

| JLB - 3119 | 25.61 | 26.67 | 400/25 | JYJYD | 400 | JY - 400L | 730 | 3770 | 5.9 |

| JLB - 3120 | 26.68 | 27.71 | 400/35, 400/50 | JYJYD | - | - | 730 | 4000 | 6.7 |

| JLB - 3121 | 27.72 | 28.87 | 400/95 | JYJYD | - | - | 760 | 4280 | 9.2 |

| JLB - 3122 | 28.88 | 30.05 | 400/95, 500/35, 500/45 | JYJYD | 500 | JY - 500L | 830 | 4460 | 9.7 |

This list only includes some products. For other products, please consult the company.

Selection Table of Preformed Armor Rods for Strengthening Conductor Splicing Sleeves

| Company Product Model | Applicable Conductor Diameter Range (mm) | Applicable Conductor Type (GB1179 - 83) | Maximum Length of Splicing Sleeve (mm) | Reference Length (mm) | Wire Weight (Kg) | ||||

| Minimum | Maximum | Steel - Reinforced Aluminum Stranded Wire LGJ/LGJF | Splicing Sleeve Model | Aluminum Stranded Wire LJ | Splicing Sleeve Model | ||||

| JLB - 3101 | 12.24 | 12.78 | - | - | 95 | JT - 95L | 280 | 1470 | 0.5 |

| JLB - 3103 | 13.26 | 13.82 | 95/15 | JT | - | - | 600 | 2010 | 0.9 |

| JLB - 3104 | 13.83 | 13.44 | 95/20 | JT | - | - | 600 | 2040 | 0.9 |

| JLB - 3105 | 14.41 | 15.09 | 120/20 | JYJTB | - | - | 430 | 2080 | 1.1 |

| JLB - 3107 | 15.72 | 16.36 | 120/25 | JY | 150 | JT/JY - 150L | 470 | 2260 | 1.2 |

| JLB - 3108 | 16.37 | 17.04 | 150/20 | JYJTB | - | - | 490 | 2250 | 1.5 |

| JLB - 3109 | 17.05 | 17.78 | 150/25, 180/35 | JYJTB | 185 | JT/JY - 185L | 530 | 2220 | 1.5 |

| JLB - 3111 | 18.53 | 19.3 | 185/25, 185/30 | JYJTB | 210 | JY - 210L | 540 | 2210 | 2.3 |

| JLB - 3112 | 19.31 | 20.12 | 185/45, 210/25 | JYJTB | 240 | JY - 240L | 570 | 2550 | 2.6 |

| JLB - 3113 | 20.17 | 20.96 | 210/35, 210/50 | JYJTB | - | - | 600 | 2760 | 2.8 |

| JLB - 3114 | 20.93 | 21.61 | 240/30, 240/40 | JYJTB | - | - | 570 | 2830 | 2.7 |

| JLB - 3115 | 21.62 | 22.5 | 240/40, 240/55 | JYJTB | 300 | JY - 300L | 640 | 3090 | 3.4 |

| JLB - 3116 | 22.51 | 23.6 | 300/15, 300/20 | JYJYD | - | - | 580 | 3180 | 4.5 |

| JLB - 3117 | 23.61 | 24.59 | 300/25, 300/40, 300/50 | JYJYD | - | - | 660 | 3410 | 5.2 |

| JLB - 3118 | 24.6 | 25.6 | 300/70 | JYJYD | - | - | 620 | 3570 | 5.6 |

| JLB - 3119 | 25.61 | 26.67 | 400/25 | JYJYD | 400 | JY - 400L | 730 | 3770 | 5.9 |

| JLB - 3120 | 26.68 | 27.71 | 400/35, 400/50 | JYJYD | - | - | 730 | 4000 | 6.7 |

| JLB - 3121 | 27.72 | 28.87 | 400/95 | JYJYD | - | - | 760 | 4280 | 9.2 |

| JLB - 3122 | 28.88 | 30.05 | 400/95, 500/35, 500/45 | JYJYD | 500 | JY - 500L | 830 | 4460 | 9.7 |

This list only includes some products. For other products, please consult the company.

Selection Table of Preformed Armor Rods for Strengthening Steel Strand Ground Wire Splicing Sleeves

| Company Product Model | Applicable Conductor Diameter Range (mm) | Applicable Conductor Type (GB1200 - 88) | Splicing Sleeve Model | Maximum Length of Splicing Sleeve (mm) | Reference Length (mm) | Wire Weight (Kg) | |

| Minimum | Maximum | Steel Strand (GJ) | |||||

| JLB - 35G | 7.4 | 8 | 35 | JY - 35G | 300 | 1790 | 0.75 |

| JLB - 50G | 8.7 | 9.1 | 50 | JY - 50G | 240 | 1900 | 0.95 |

| JLB - 70G | 10.5 | 11.1 | 70 | JY - 70G | 290 | 2400 | 2.1 |

| JLB - 80G | 11.4 | 11.8 | 80 | JY - 80G | 260 | 2330 | 1.9 |

| JLB - 100G | 12.9 | 13.3 | 100 | JY - 100G | 320 | 3270 | 4 |

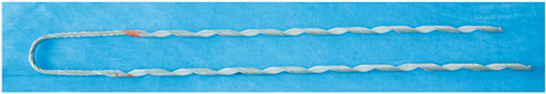

Preformed Conductor Splicing Strips (SJLD)

Ⅰ. Component Description

① Grouped strips: Generally composed of 2, 3, or 4 sets of preformed wires, with the inner surface sandblasted.

② Installation mark: Different colors distinguish product models; marks are also made at the center of the product as installation guides for easier assembly.

③ Label: Indicates the product model and applicable conductor specifications.

④ Length: Refer to the selection table for details.

Purpose

Preformed conductor splicing strips are designed solely as independent external connection components for high-voltage lines (< 345 kV).

Type Selection Table for Preformed Full-Tension Splice Kits(SJLD)

| Company Product Model No. | Industry Standard Model No. | Applicable Conductor Type | Reference Splice Length (mm) | Splice Weight (kg) | |||||

| Steel Core | Filler | Outer Layer | Steel Core | Filler | Outer Layer | ||||

| LQ-33/6 | GB1179-83/GB1179-74 | LGJ-33/6 | 356 | - | - | 1066 | 0.88 | 0.18 | |

| LQ-50/8 | JL-50/8 | LGJ-50/8 | 608 | - | - | 1727 | 0.15 | 0.35 | |

| LQ-50/30 | JL-50/30 | LGJ-50/30 | 617 | 608 | - | 1727 | 0.23 | 0.75 | |

| LQ-70/10 | JL-70/10 | LGJ-70/10 | 627 | 606 | - | 1499 | 0.37 | 0.6 | |

| LQ-70/40 | JL-70/40 | LGJ-70/40 | 627 | 606 | 486 | 2240 | 0.71 | 0.1 | 1.26 |

| LQ-95/25 | JL-95/25 | LGJ-95/25 | 777 | 790 | - | 1777 | 1.61 | - | 0.77 |

| LQ-95/55 | JL-95/55 | LGJ-95/55 | 777 | 710 | 508 | 2560 | 0.65 | 0.1 | 0.99 |

| LQ-95/20 | JL-95/20 | LGJ-95/20 | 767 | 707 | - | 1880 | 0.15 | - | 0.83 |

| LQ-120/70 | JL-120/70 | LGJ-120/70 | 247 | 538 | 537 | 2077 | 0.15 | 0.12 | 1.09 |

| LQ-120/25 | JL-120/25 | LGJ-120/25 | 777 | 559 | 559 | 1962 | 0.18 | 0.1 | 1.43 |

| LQ-150/8 | JL-150/8 | LGJ-150/8 | 887 | 856 | 856 | 2188 | 0.67 | 0.14 | 1.24 |

| LQ-150/20 | JL-150/20 | LGJ-150/20 | 887 | 856 | 856 | 2187 | 0.65 | 0.14 | 1.29 |

| LQ-150/25 | JL-150/25 | LGJ-150/25 | 247 | 608 | 608 | 2241 | 0.19 | 0.14 | 1.51 |

| LQ-150/70 | JL-150/70 | LGJ-150/70 | 247 | 608 | 608 | 2243 | 0.19 | 0.14 | 1.54 |

| LQ-185/15 | JL-185/15 | LGJ-185/15 | 387 | 632 | 632 | 2385 | 0.22 | 0.15 | 1.49 |

| LQ-185/30 | JL-185/30 | LGJ-185/30 | 817 | 686 | 686 | 2468 | 0.19 | 0.15 | 2.15 |

| LQ-185/25 | JL-185/25 | LGJ-185/25 | 247 | 787 | 787 | 2862 | 0.47 | 0.23 | 2.42 |

| LQ-185/45 | JL-185/45 | LGJ-185/45 | 247 | 787 | 787 | 2864 | 0.49 | 0.23 | 2.44 |

| LQ-185/90 | JL-185/90 | LGJ-185/90 | 187 | 606 | 606 | 2693 | 0.29 | 0.18 | 2.26 |

| LQ-210/10 | JL-210/10 | LGJ-210/10 | 887 | 686 | 686 | 2412 | 0.29 | 0.17 | 2.46 |

| LQ-210/25 | JL-210/25 | LGJ-210/25 | 247 | 711 | 711 | 2743 | 0.19 | 0.27 | 2.75 |

| LQ-210/50 | JL-210/50 | LGJ-210/50 | 247 | 787 | 787 | 2845 | 0.38 | 0.35 | 2.86 |

| LQ-240/10 | JL-240/10 | LGJ-240/10 | 387 | 787 | 787 | 3245 | 0.47 | 0.37 | 3.42 |

| LQ-240/30 | JL-240/30 | LGJ-240/30 | 817 | 838 | 838 | 3673 | 0.54 | 0.33 | 3.45 |

| LQ-240/55 | JL-240/55 | LGJ-240/55 | 247 | 777 | 777 | 3050 | 0.34 | 0.32 | 3.86 |

| LQ-240/10(I) | JL-240/10(I) | LGJ-240/10(I) | 247 | 688 | 688 | 3124 | 0.29 | 0.32 | 3.76 |

| LQ-300/19 | JL-300/19 | LGJ-300/19 | 247 | 711 | 711 | 3429 | 0.33 | 0.31 | 5.22 |

| LQ-300/25 | JL-300/25 | LGJ-300/25 | 437 | 659 | 659 | 3429 | 0.26 | 0.39 | 4.81 |

| LQ-300/40 | JL-300/40 | LGJ-300/40 | 247 | 787 | 787 | 3429 | 0.34 | 0.42 | 5.24 |

| LQ-300/50 | JL-300/50 | LGJ-300/50 | 247 | 787 | 787 | 3480 | 0.47 | 0.42 | 5.38 |

| LQ-300/70 | JL-300/70 | LGJ-300/70 | 287 | 914 | 914 | 3531 | 0.59 | 0.58 | 5.49 |

| LQ-300/90 | JL-300/90 | LGJ-300/90 | 319 | 914 | 914 | 3677 | 0.59 | 0.59 | 5.67 |

| LQ-400/25 | JL-400/25 | LGJ-400/25 | 427 | 630 | 630 | 4166 | 0.26 | 0.53 | 7.13 |

| LQ-400/30 | JL-400/30 | LGJ-400/30 | 427 | 630 | 630 | 4333 | 0.19 | 0.53 | 8.35 |

| LQ-400/50 | JL-400/50 | LGJ-400/50 | 427 | 689 | 689 | 3554 | 0.29 | 0.52 | 7.03 |

| LQ-400/65 | JL-400/65 | LGJ-400/65 | 427 | 836 | 836 | 4246 | 0.29 | 0.71 | 8.63 |

| LQ-400/85 | JL-400/85 | LGJ-400/85 | 427 | 1168 | 1168 | 4291 | 0.54 | 0.88 | 9.31 |

| LQ-400/95 | JL-400/95 | LGJ-400/95 | 3619 | 1219 | 1219 | 4216 | 0.84 | 0.77 | 9.21 |

Note: Meanings of letters and numbers in the model:

J = Splice strip

L = Spiral preformed type

Q = Full - tension

Numbers = Corresponding conductor model of the product

0 = Applicable to steel - cored aluminum stranded wires in GB1179 - 74

This table only lists some products. For other products, please consult the company.